Custom Coils

Custom Coils

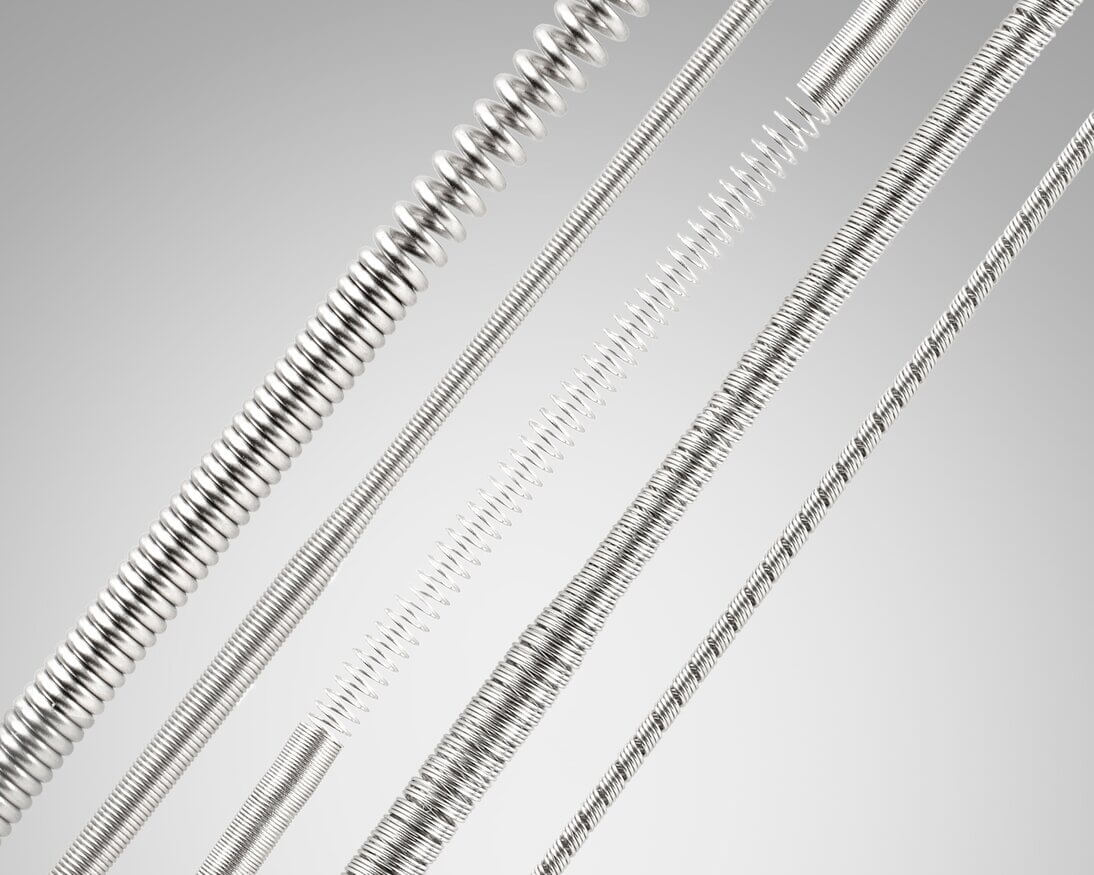

Custom coils are designed, engineered, and manufactured in spiral and helix formats using materials for custom medical, heating, and micro applications. Our ISO 13485.2016 certified custom coils manufacturing process uses your specifications and parameters to create an end product that meets your application needs.

Have you been searching for a custom coil solution that meets your needs? For nearly 40 years, Thermetic Products has provided custom coils solutions for aerospace, medical, heating, and 3-D printing. To learn more about Thermetic and what solutions we can offer you. For more information, contact us via email at info@thermetic.com.

Medical Coils

Coils manufactured for the medical industry are an integral part of the design and assembly process of medical device production.

Various uses for industrial coils include:

- Fluoroscopic imaging

- Electrical leads for stimulation devices

- Catheter support

Heating Coils

Heating systems require coils to transform electrical energy into heat energy. Our custom coils are manufactured to meet your unique heating specifications, meeting your exclusive application needs.

Industrial heating coils should be designed based on the following:

- Alloy requirements

- Element type

- Shape

Heating Coil Manufacturing Requirements

Choosing a proper alloy for the application is essential when manufacturing heating coils. Characteristics of the alloy should adequately align with the needs of the coil and be determined by:

- Resistance to oxidation

- Reliable resistance

- Melting point

- Propensity for corrosion

- Expansion

Open & Covered Heating Coil Advantages

Coils used for heating applications can be covered or open, depending on the desired result.

Benefits to open element heating coils:

- Low maintenance, easy-to-replace parts

- Rapid heating times

- Susceptible to damage

Covered element heating coil benefits include:

- Direct heating processes are more corrosive

- Protective sheath reduces the risk of electrocution and fires

Choosing the proper custom coil for your heating element avoids wasted energy and ensures the optimal heating area is covered.

Micro Coils

Custom micro coils perform similar functions to regular coils but are minuscule. Often, working with micro coils requires a magnifying glass or microscope.

Micro Coil Applicable Size Options

At Thermetic Medical, we can wind a coil using a wire as small as .001” to a coil with an OD of .005”.

Contact Thermetic Products for Custom Coils Solutions Today

In the market for custom coils solutions for your application? Thermetic Products, Inc. is your industrial coil manufacturer and has over 30 years of trusted industrial custom coils manufacturing experience. Contact us or request a quote for direct pricing information today.